-

The working principle and application of continuous weightless scaleTime of issue : 2022-01-05

The working principle and application of continuous weightless scaleTime of issue : 2022-01-05In various fields of modern industrial production, the use of continuous feeding with dynamic weighing function to form a bulk material conveying system is expanding.

-

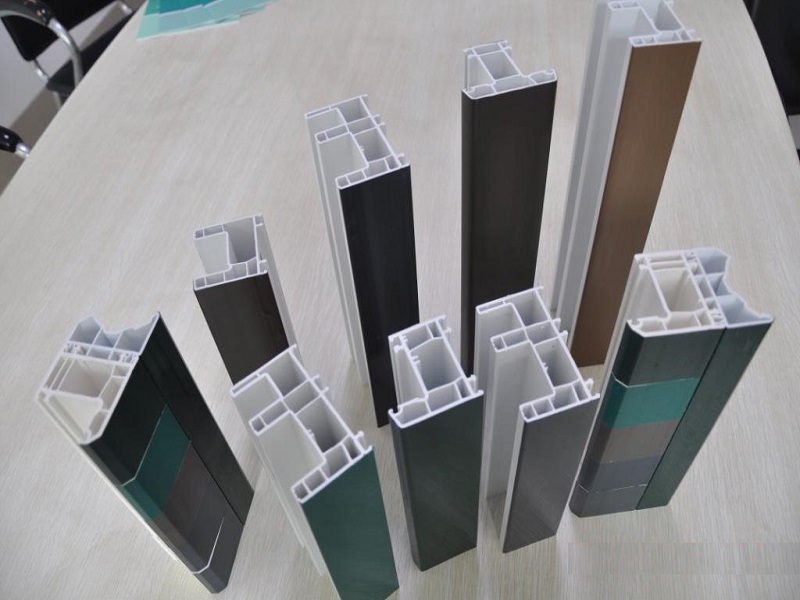

Analysis of mixing technology and mixing effect of PVC rigid productsTime of issue : 2021-12-29

Analysis of mixing technology and mixing effect of PVC rigid productsTime of issue : 2021-12-29The mixing of U-PVC formulations usually goes through two stages of hot mixing and cold mixing.

-

What are the effects of material characteristics on the selection of pneumatic conveying systems?Time of issue : 2021-07-16

What are the effects of material characteristics on the selection of pneumatic conveying systems?Time of issue : 2021-07-16Material characteristics are the basis for the selection of pneumatic conveying systems. According to different material characteristics, we need to select appropriate system types and components to achieve the ideal conveying effect. Precautions for the selection of some typical material characteristics.

-

How to transform the injection molding industry in manufacturing plants?Time of issue : 2021-07-16

How to transform the injection molding industry in manufacturing plants?Time of issue : 2021-07-16In recent years, the upsurge of smart manufacturing has swept across China, and major economies around the world are vigorously promoting the revival of the manufacturing industry, and many outstanding manufacturing companies have carried out smart factory construction practices. Industry 4.0, Industrial Internet, Internet of Things, cloud computing and other crazes have become the most important measures to promote the "Made in China 2025" national strategy, including the transformation of enterprises in the injection molding industry.

-

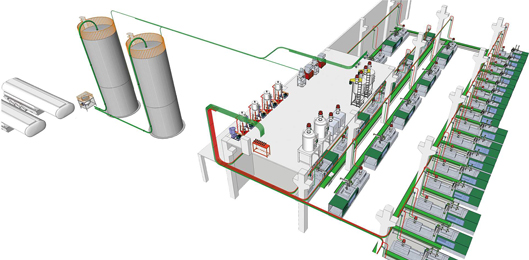

The installation process of the central feeding systemTime of issue : 2021-07-16

The installation process of the central feeding systemTime of issue : 2021-07-16The central feeding system can reduce the pollution of raw materials and dust to the injection molding production to the lowest level, so as to maintain a clean production workshop. The central feeding system has a unique centralized dust recovery system, which makes cleaning more convenient and has an environmental protection effect. The 10,000-class clean room requires standards for operation and reduces noise. Finally, unmanned automated production workshops can be realized, and the image of modern factory management can be established.

-

What are the performance of the automatic feeding system equipment?Time of issue : 2021-07-16

What are the performance of the automatic feeding system equipment?Time of issue : 2021-07-16At present, the quality of automatic feeding system equipment on the market varies from good to bad. Many non-professional production companies also set foot in this market. They are shoddy and form a bad competition trend, which disrupts the professional market of automatic feeding systems.

-

What are the advantages of pneumatic conveying compared to other forms of conveying?Time of issue : 2021-07-16

What are the advantages of pneumatic conveying compared to other forms of conveying?Time of issue : 2021-07-16Low maintenance, low labor, low cost, the pneumatic transmission line is composed of closed and smooth pipelines, and there are no mechanical moving parts.

-

Where are the application advantages of the central feeding system?Time of issue : 2021-07-16

Where are the application advantages of the central feeding system?Time of issue : 2021-07-16With the rapid development of the plastics industry, the central feeding system is widely used in injection molding workshops, which can realize various special requirements such as raw material transportation, dehumidification, drying, color matching, metering, mixing, etc., saving manpower, financial resources, material resources and time for enterprises To reduce costs and increase revenue, it is an important production equipment indispensable for the plastics industry at present.

-

Pipeline layout requirements of the central feeding systemTime of issue : 2021-07-16

Pipeline layout requirements of the central feeding systemTime of issue : 2021-07-16The pipeline is an indispensable connecting device for the central feeding system. If it is not well laid out, the impact will be particularly great. Therefore, the pipeline layout of the central feeding system must follow the basic layout principles to ensure efficient and smooth production.

-

The development prospect of automatic feeding system in intelligent chemical factoryTime of issue : 2021-07-16

The development prospect of automatic feeding system in intelligent chemical factoryTime of issue : 2021-07-16With the support of new technologies, modern industry is moving from traditional automated production to intelligentization. In this process, it will also drive the growth of the automation equipment market. Among them, the automated feeding system is one of the control components, and the industrial market is expanding.

Minco Intelligent Equipment Technology (Nantong) Co., Ltd.

Add:Pingchao, Tongzhou district, Nantong city, Jiangsu province

Tel:+86-513-69962378

Fax:+86-513-69962378

P.C.:226300

Copyright © Minco Intelligent Equipment Technology (Nantong) Co., Ltd. All Rights Reserved 京ICP證000000号

+86-513-69962378

+86-513-69962378

Feedback

Feedback